Hanbi focus on the development of environmentally friendly disposable products. The company has 20 patented technologies and an annual production capacity of 100 million sets. The main products include straw toothbrush, PLA comb and other degradable toiletry sets, with a degradation rate of more than 90%. Passed ISO9001 and ISO14001 certification, serving more than 500 customers. Hampe is committed to providing green solutions for the hotel industry, reducing plastic use by 300 tons per year.

5-dimensional Cost Reduction and Efficiency Improvement Rules for Hotel Consumables Procurement"!

"Save a Million a Year! 5-dimensional Cost Reduction and Efficiency Improvement Rules for Hotel Consumables Procurement"

I. Materials: Three yardsticks to Avoid the "pseudo-upgrade" Trap

The life-and-death line of plastic products

Toothbrush/comb: Choose food-grade PP (polypropylene)

The test report must contain BPA < 0.01% (EU No.10/2011 standard)

The roundness rate of the bristles is ≥90% (National standard GB 19342-2013) to prevent complaints about gum bleeding

Slippers: Corn fiber +EVA foam soles

→ Load-bearing capacity > 150kg (200 jin customers won't collapse under their feet) + 45 days of natural degradation

2. Fatal parameters for linen

Category:

Weight: Towel ≥550g (bath towel). Process: 60s untwisted yarn →200 washes to become fluffy

Weight: Bathrobe ≥280g/㎡ \ nProcess: Double-needle stitching → anti-tear under the armpit

3. Formula for converting consumables costs

The true cost per item = purchase price + (negative review compensation rate × average transaction value) + inventory loss

Case: A certain chain hotel purchased a low-quality toothbrush for 0.9 yuan → the negative review rate was 18%→ the compensation cost was 15 yuan per room → the actual cost was 16.2 yuan

Environmental Protection: The Leap from "Compliance Burden" to "Profit Engine":

1. Certification segment map

Bronze: Degradable Mark (No authoritative certification)

Gold: **FSC Forest Certification ** (Wood products) + **OK Compost Industrial Composting Certification **

King: **GRS Global Recycling Standard ** (Including Recycled Material Traceability System)

2. Practical Path of Environmental Premium

Customer acquisition end: Ctrip's "Low-Carbon Hotel" tag → Traffic bias + ranking weighting

Policy end: Application for Green Hotel → 30% reduction in pollution discharge fees (Example: Hangzhou Huanglong Hotel)

Cost side: The purchase price of corn fiber slippers is high at ¥0.8 → but the logistics compression rate is ↑40% (saving shipping cost ¥0.3) + the loss rate is ↓25%

Suppliers: Lock in long-term partners with "military standards"

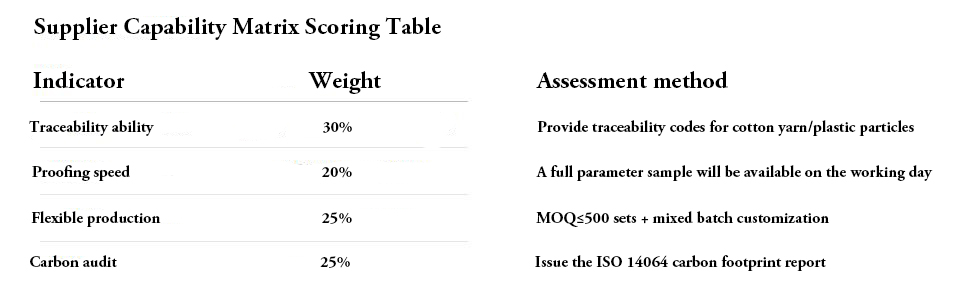

Supplier Capability Matrix Scoring Table

A painful lesson: A five-star hotel lost an order for a multinational company's annual meeting (with a loss of 1.2 million yuan) due to its supplier's lack of GRS certification.

Cost Explosion Point: The Invisible Profit Black Hole

1. A covert battle over freight charges

Compression technology: Vacuum compression of corn fiber slippers → 150,000 pairs more in 40-foot cabinets → Freight cost ↓¥0.17 per pair

Local supporting facilities: Select a laundry with a radius of no more than 200 kilometers → The transportation cost of linen will be reduced by ¥0.8 per kilogram

2. Loss rate control formula

The loss rate of toothbrushes = the rate of defective products + the rate of customers taking them away + the rate of expired inventory

Dimensionality reduction strategy:

Toothbrushes no longer have individual packaging → Reduce inventory expiration by 15%

The weight of the shower cap has increased from 2g to 3g → Damage complaints ↓70% (cost has only increased by ¥0.03)

V. Ultimate Decision Model: Crushing Empiricism with Algorithms

Comprehensive Value Scoring Table of Consumables

The total score = (Safety factor ×0.3) + (True cost per item ×0.3) + (Environmental protection grade ×0.2) + (Supply stability ×0.2)

Operation example:

Toothbrush A: Safety score 90 + Cost ¥0.12 + Environmental gold grade + Supply score 80 → Total score 83.6

Toothbrush B: Safety score 60 + Cost ¥0.08 + Environmental protection without certification + Supply score 95 → Total score 68.3

Decision: Even if B is 33% cheaper, still choose A to reduce long-term risks