Hotel bed: Ingenuity, to create a comfortable sleep experience!

Hotel bedding, as the "first impression" of guests close contact with the hotel, its quality directly affects the guest's stay experience.

Quality hotel bedding, not only need to have a soft and comfortable touch, but also durable, easy to take care of. Behind this, it is

inseparable from exquisite craftsmanship and the pursuit of details.

First, select high-quality raw materials to lay a comfortable foundation

The quality of hotel bedding first depends on the choice of raw materials.

High count and density fabric: High count yarn means thinner fiber, high density represents a tighter weaving process, the combination

of the two create a delicate, soft, breathable skin experience. At present, more than 60 high-count high-density cotton fabrics have

become the first choice for high-end hotels.

Functional fibers: In addition to pure cotton, some hotels also choose to add functional fibers, such as tencel, modal, etc., to enhance

the dryness, gloss and antibacterial properties of the fabric.

Quality fillers: The fillers of the core and pillow directly affect the comfort of sleep. High-quality natural materials such as down, feather

and silk, as well as specially treated chemical fiber materials, can provide a light, fluffy, warm and breathable sleeping environment.

Second, exquisite weaving technology to create a delicate texture

High-quality raw materials require exquisite craftsmanship to glow with real value.

Advanced weaving equipment: imported rapier loom, air-jet loom and other advanced equipment are used to ensure uniform weaving of

fabrics and reduce defects.

Special finishing process: pre-shrink treatment, mercerizing treatment, grinding treatment and other finishing processes can further enhance

the softness, gloss and durability of the fabric.

Environmental protection printing and dyeing technology: The use of active printing and digital printing and other environmental protection

technologies to ensure bright and lasting colors, while reducing environmental pollution.

3. Strict quality control standards to ensure consistent quality

Hotel bedding is used frequently and needs to be tested by repeated washing and disinfection, so the durability and color fastness of the

product are very high.

Strict quality testing: From raw materials to finished products, each process has undergone strict quality testing to ensure that products meet

national standards and hotel requirements.

Professional washing test: Simulate the actual washing environment of the hotel, and carry out several washing tests on the bed to ensure

that its color fastness, shrinkage rate, pilling rate and other indicators meet the standard.

Perfect after-sales service system: to provide professional after-sales service, timely solve the problems encountered in the use of the hotel,

to protect the rights and interests of the hotel.

Fourth, pay attention to detail design, improve user experience

In addition to basic comfort and durability, hotel bedding is also increasingly focused on detail design to enhance the user experience.

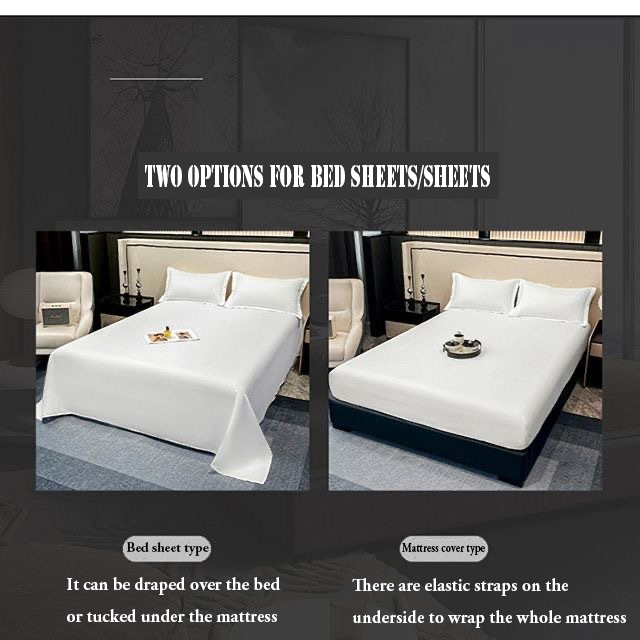

User-friendly size design: According to different bed types and user needs, provide a variety of size options to ensure that the bed and the

mattress perfectly fit.

Exquisite style design: simple and generous solid color style, elegant and fashionable jacquard style, personalized printing style, to meet the

decoration style and aesthetic needs of different hotels.

Convenient functional design: For example, bed Angle fixed belt, pillowcase anti-slip design, convenient hotel bed, improve service efficiency.

Conclusion:

Hotel bedding, seemingly simple, but contains the ultimate pursuit of quality and detail. From raw material selection to process production, from

quality detection to detail design, every link embodies the wisdom and sweat of the craftsman. It is believed that with the progress of science and

technology and the continuous innovation of technology, hotel bedding will bring us more comfortable, healthy and beautiful sleep experience.